Digitalisation via UMS

Intretech has been at the forefront of Industry 4.0 since its foundation. With its self developed United Management System (UMS) + Automation capabilities, Intretech has been able to transform manufacturing processes to consistently provide excellent services for its customers.

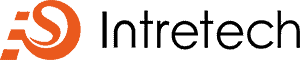

United Management System (UMS)

Intretech’s self developed UMS system is a customisable digital information integration system combining operation processes, factory management and other enterprises requirements. The aim is to provide the most comprehensive Lean Manufacturing solution.

UMS is used for the entire product life cycle management in the manufacturing industry, including production planning, material purchasing, work order, quality tracking, data collection, packaging, serial tracking and inventory management.

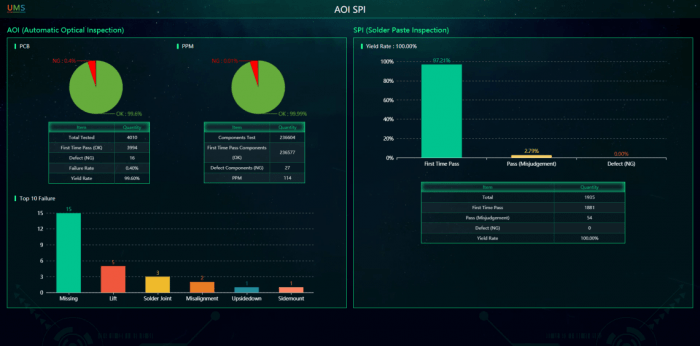

Live Data Feed

UMS provides customisable digital boards for every sector of a manufacturing site so no information is ever lost.

- Production Plan Management: Automatic management of the production scheduling through combining workshop resources such as operators, machinery, materials, operation process, production capacity.

- Just-in-time Production Control: Real-time production status monitoring including: product, component, operator, machine, process and production line, helping managers deploy production tasks according to actual production demand and resources available

- Quality Control: Real-time data of production models, station, project quality inspection, and automatic alert and recording of production issues. Using the live data, executive staff can resolve issues arising in a timely manner

- Process Tracking: Each product is bound with a serial number and form a complete dataset during its production process. Customers can review meticulous and precise production information such as operators, machines, time and other manufacturing parameters for every single product.

- Real-time Production Warning: UMS provides managers a timely solution to monitor all conditions arising during production according to parameters defined for each process. When actual production deviates from the set target and produces abnormality, UMS will give real-time feedback and alerts to managers

Enter the era of Industry 4.0

Digitalise your manufacturing data and automate your production lines by contacting us below