Automation

Intretech has been at the forefront of Industry 4.0 since its foundation. With its self developed United Management System (UMS) + Automation capabilities, Intretech has been able to transform manufacturing processes to consistently provide excellent services for its customers.

Automation

Intretech’s core capabilities include its automation systems, continually developed according to production and customer needs.

- 300+ engineers in automation

- 100+ of non-standard automatic equipment

- 10,000+ jigs & fixtures developed annually

- Own manufacturing plant for development of automation equipment

- Deep integration with UMS system

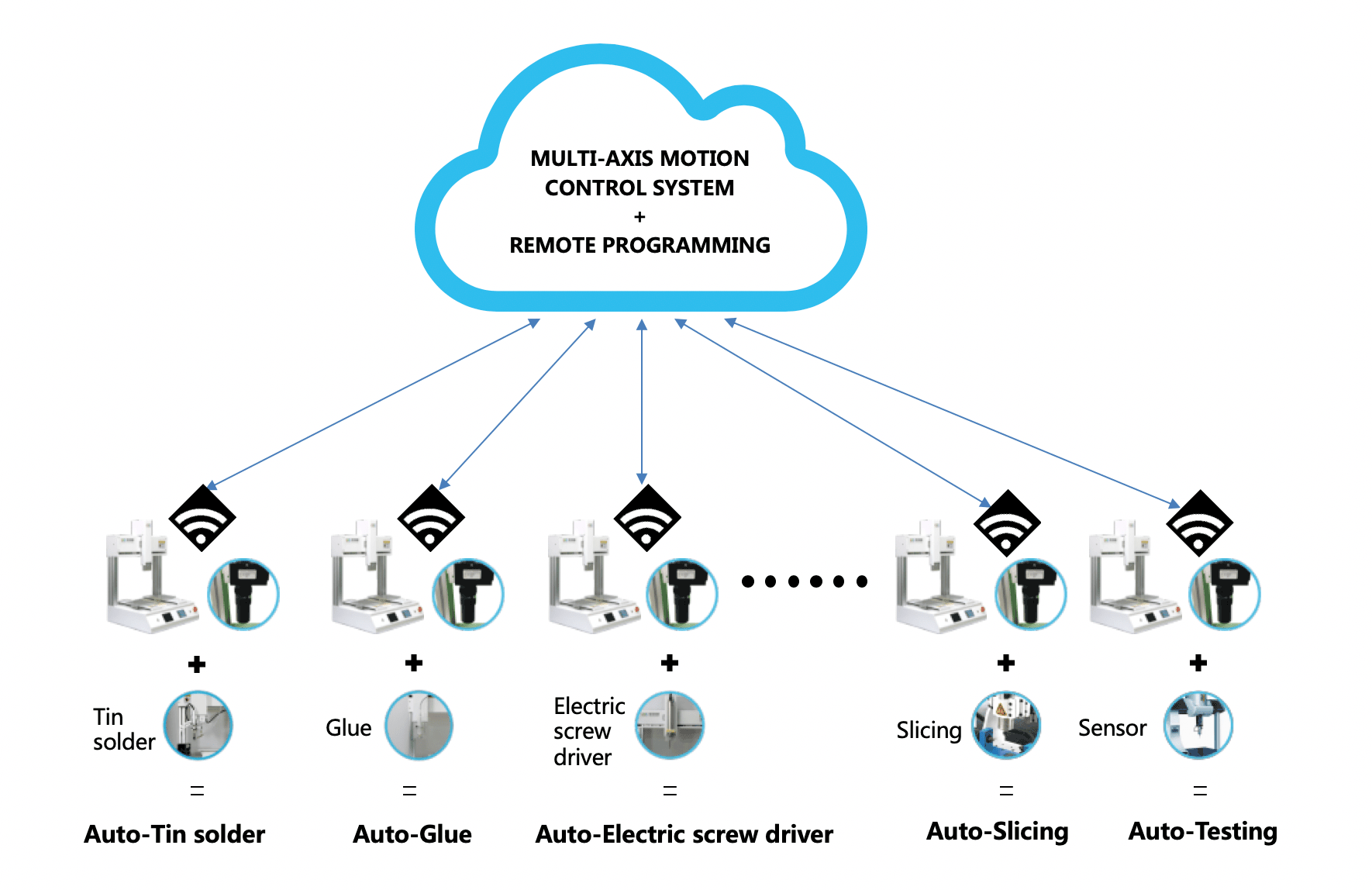

Multi-axis motion control system

By combining standard assembly fixtures with various processes, Intretech has been able to create semi and fully automated assembly lines to improve efficiency. The Multi-axis Motion Control System allows for remote monitoring, programming and automating of various manufacturing processes:

- Auto-Tin Solder

- Auto-Glue

- Auto-Electric Screw Driver

- Auto-Slicing

- Auto-Testing

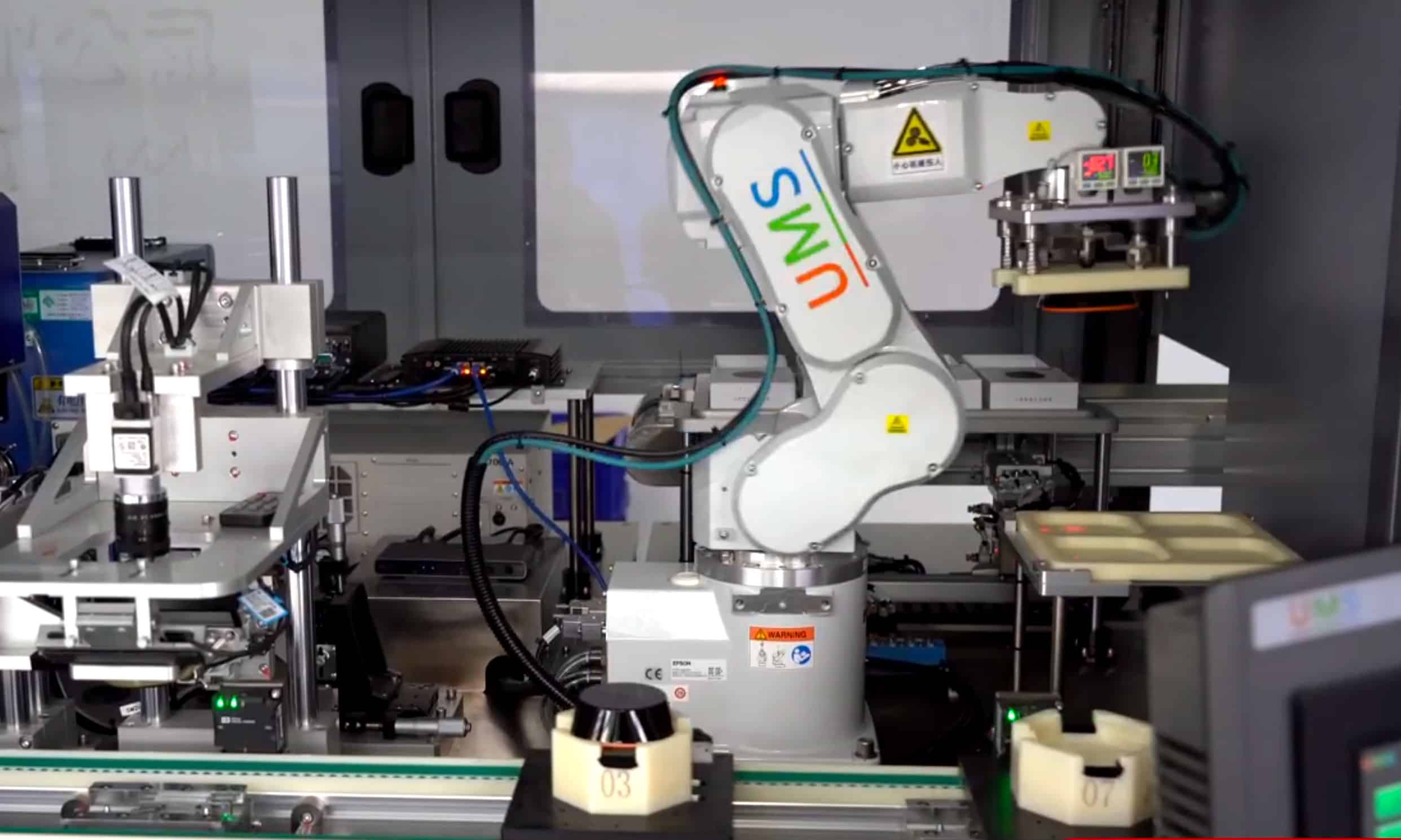

Industrial Robotics

- Industrial four / six axis robot applications

- Non-standard automation systems:

- Auto Assembly of Injection Moulding Parts

- Auto Film Mulching

- Auto Foam Sticking

- Material Processing

- Precision robotic assembly processes:

- Dome attaching

- Parts assembling

- Testing

- Packaging